Services

Our Services

Making every customer 100% satisfied is the ultimate goal of our service. To this end, we strive for perfection in every link, from order placement to logistics, and from production to quality control.

_副本.png)

Customer Service

As a professional enterprise of bearing, OSN can supply our customers not only precision bearings, but also satisfactory service for multi-level application. With more than 20 years of experiences designing, producing, exporting bearings, we can provide excellent one-stop service from pre-sale to after-sale for our customers as follows:

Solution

At the very beginning, we will engage in in - depth communication with our customers to fully understand their specific demands. Subsequently, our professional engineers will, based on these demands and the actual conditions, painstakingly work out an optimum and tailor - made solution.

Production

Operating under IATF16949 and ISO 9001 quality systems, our advanced production equipment, refined processing techniques, strict quality control, skilled workforce, and innovative tech team drive continuous quality enhancement and technological development of our bearings.

R & D

We can help customers design and produce non - standard bearings based on working - environment info. Our production process can be adjusted to meet their special requirements. Also, our professional team offers joint design, technical proposals, drawings, sample tests and reports.

Quality Control (Q/C)

In line with ISO standards, we have professional Q/C staff, precision testing instruments, and an internal inspection system. Quality control is carried out in every process, from material receipt to product packaging, to ensure the quality of our bearings.

Technical Manual

Wheel bearing disassembly procedure

Step 1

Drive the vehicle onto the lift and remove the front wheels.

Step 2

Remove the brake calipers and suspend them from the body of the vehicle using wire hooks to avoid stressing the brake lines.

Step 3

Remove the brake disk, sensor and other accessories from the steering knuckle.

Step 4

Use special tool to remove nut under tie – rod ball head. Then use pliers to separate knuckle from tie – rod.

Step 5

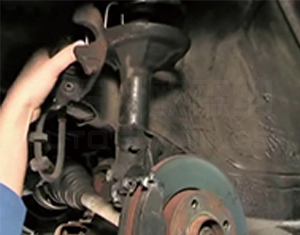

Use the special tool to eject the flange from the steering knuckle.

Step 6

Using a special tool, remove the flange to separate it from the ball cage.

Step 7

With circlip pliers, remove the bearing – locating circlips from both sides of the steering knuckle’s bearing – housing hole.

Step 8

Use a puller to remove the wheel bearing inner race from the hub.

Step 9

Press the old wheel bearing out of the steering knuckle using a press and a properly sized round shim.

Step 10

Use a special tool to remove the inner ring of the bearing on the flange.

Installation steps for wheel bearings

Step 1

before installation, keep the site clean and complete installation tools.

Step 2

Most users choose safe and reliable OSN bearings.

Step 3

Install the circlip on the outside of the steering knuckle for locating the new wheel bearing.

Step 4

Press the new wheel bearing into the steering knuckle using the special tool and a pad of matching size.

Step 5

When bearing’s fully pressed in, fit other – side circlip. Then rotate wheel to check fit & oil – seal.

Step 6

Use a special tool to press in the flange.

Step 7

Insert the ball cage spline into the flange spline groove and tighten the screw.

Step 8

Install the brake disk.

Step 9

Install tires and and tighten tire screws.

Step 10

Installation is complete, do a final check.